BLANKETS & SPECIALTIES

FIBERFRAX® / INSULFRAX® / ISOFRAX® / EXCELFRAX® / SILPLATE® MASS 1500

FIBERFRAX® BLANKETS & MATS

The Fiberfrax® blanket and mat product family is a group

of lightweight, thermally efficient ceramic fiber insulating

materials that combine the advantages of dimensional stability

at high temperatures with complete resistance to thermal

shock. Featuring a broad range of thermal capabilities and

physical characteristics, this product family provides proven

and effective solutions to a variety of heat processing

applications.

- Specific Product Characteristics

- Extremely low shrinkage: Fibermax Mat

- Low shrinkage: Durablanket 2600 insulation

- Exceptional handling strength: Durablanket 2600 insulation,Durablanket S insulation, Durablanket HP-S insulation,Fibermat Blanket

- Exceptional hot strength: Durablanket 2600 insulation

- Exceptional velocity resistance: Moist Pak-D insulation

- Excellent conformance to complex shapes: Moist Pak-D

insulation - Low shot content (95% fiber index): Fibermax Mat

- Exceptional sound absorption: Fibermat Blanket, PH blanket

- High resiliency: Fibermax Mat

- Excellent compression recovery: Fibermat Blanket

- Excellent filtration capabilities: PH blanket

Fiberfrax® Blankt Family of products:

- Durablanket® 2600

- Durablanket S

- Durablanket HP-S

- Duraback®

- Fibermat® Blanket

- PH Blanket

- Moist Pak-D®

- Fibermax® Mat

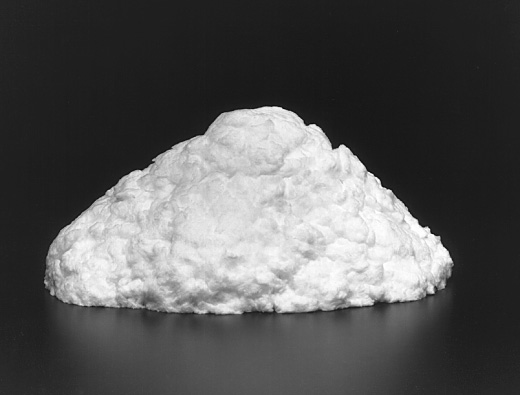

FIBERFRAX® BULK FIBER

Fiberfrax® ceramic fibers are a family of high-temperature

fibers designed to be used in a variety of industrial and

commercial applications. Manufactured from alumina-silica

materials, Fiberfrax fibers are chemically inert. Some of the

unique properties these fibers offer are:

• High-temperature stability

• Low thermal conductivity

• Low heat storage

• Excellent thermal shock resistance

• Lightweight

Fiberfrax fibers are available in a variety of chemistries and

diameters which can service a wide variety of applications. In

addition, these fibers can be further modified by chopping or

by removal of the unfiberized particles (called shot). Lubricants

can also be added to the fiber to enhance fiber properties.

Fiberfrax fibers exhibit excellent chemical stability and

resistance to attack from most corrosive agents. Exceptions

include hydrofluoric acid, phosphoric acid and strong alkalis.

Fiberfrax fibers also effectively resist oxidation and reduction.

If wet by water or steam, thermal and physical properties

are restored upon drying. Fiberfrax fibers contain no water

of hydration.

Fiberfrax® Bulk Family of products:

- Fiberfrax 7000 Series Fiber

- Fiberfrax 6000 Series

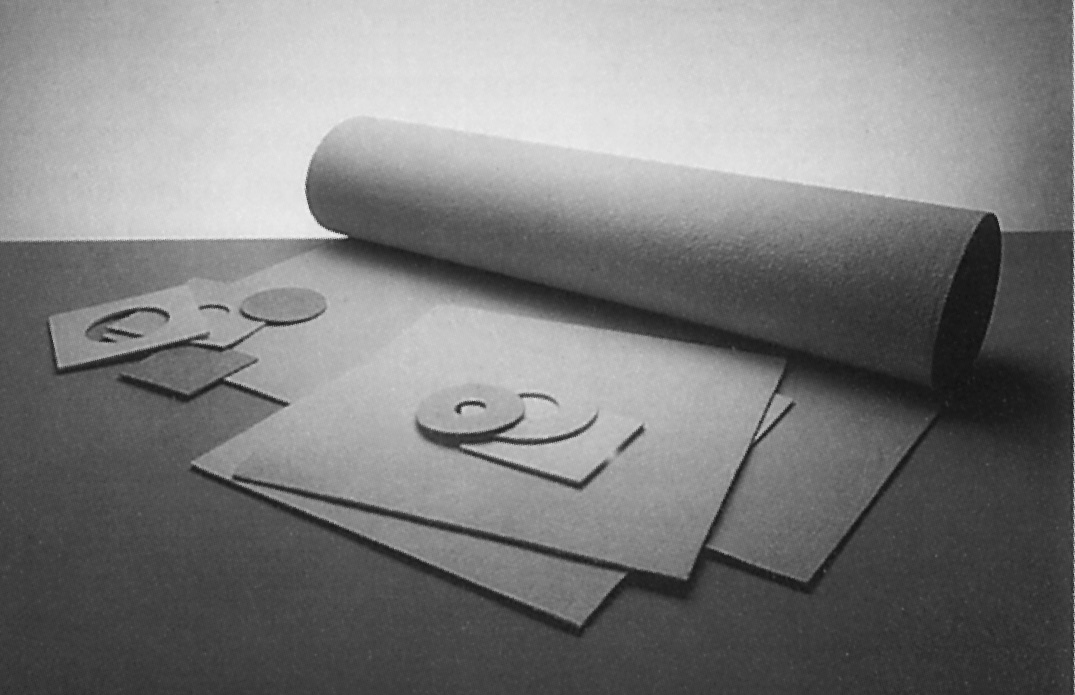

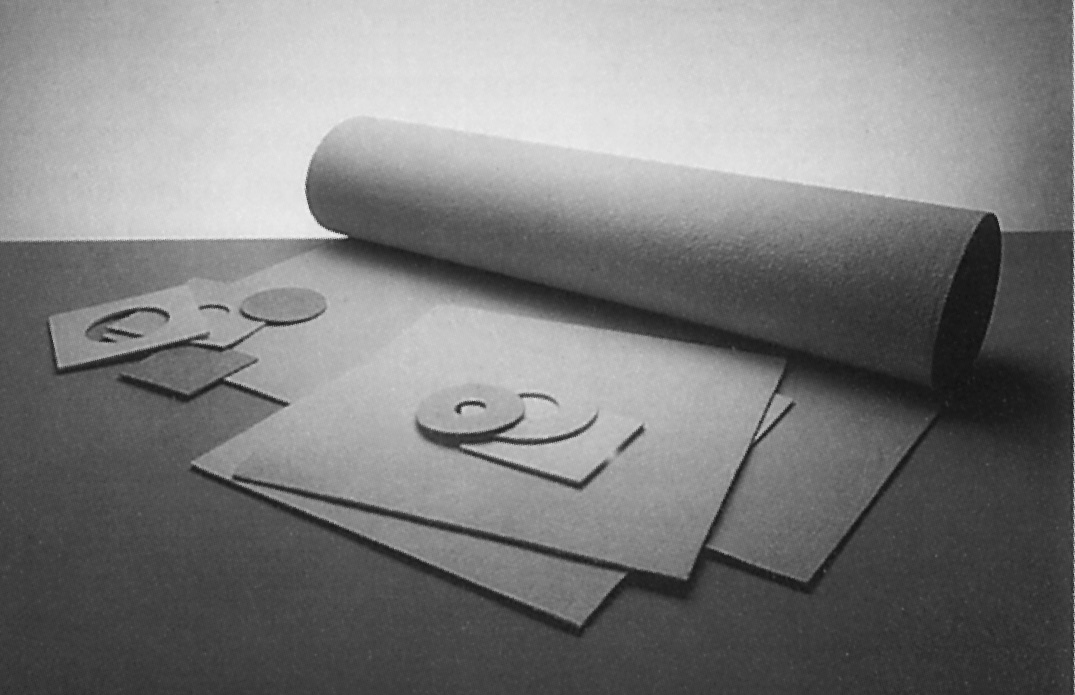

FIBERFRAX® FELT PRODUCTS

Fiberfrax® Lo-Con™ felt and Duraset® felt are unique product

forms in the Unifrax Corporation’s extensive ceramic fiber

product family. Felt products extend the performance of

Fiberfrax papers in a product form with lower densities and

increased mat thickness. Felt products are compressible but

resilient; they conform to irregular surfaces yet have sufficient

integrity to hold their shape in gaskets and formed parts.

Both felt grades are wet laid, uniform, ceramic fiber mats

which have been impregnated with a thermosetting resin.

In Lo-Con felt, this resin has been precured to produce a

semi-flexible rolled sheet available in different densities and

thicknesses. The binders in Duraset have been left uncured

so they can be molded under heat and pressure to retain a

complex shape after processing.

The organic binders remain functional at low and

moderate temperatures (to 650°F); however, the core

ceramic fiber materials will provide consistent performance

at temperatures well in excess of 2000°F, providing excellent

thermal insulation in a wide range of applications.

Fiberfrax® Felt Family of products:

- Lo-Con™

- Binder Free Lo-Con™

- Duraset®

FIBERFRAX® PAPER PRODUCTS

The Fiberfrax® ceramic fiber paper product line is a unique

family of products which is manufactured by forming aluminosilicate

fibers in a nonwoven matrix. The ceramic fibers are randomly

orientated during manufacture, then held in place with a

latex binder system. A specialized paper-making process is

statistically controlled to form uniform, lightweight, flexible sheets.

Unifrax has been producing Fiberfrax papers for over 25

years and is the largest ceramic fiber producer worldwide with

in-house paper-making capabilities.

By blending different fibers, binders, and additives while

varying the manufacturing process, Unifrax now produces a variety

of Fiberfrax paper products for a wide range of applications.

Fiberfrax papers exhibit excellent chemical stability, resisting

attack from most corrosive agents. Exceptions are hydrofluoric,

phosphoric acids and concentrated alkalies. If Fiberfrax papers

are wet by water or steam, all thermal and physical properties

are completely restored upon drying. No water of hydration is

present in most Fiberfrax paper grades. Fiberfrax papers have

good dielectric strengths.

Fiberfrax papers, with the exception of the inorganic series,

will generate small amounts of smoke and trace element outgassing

during the initial exposure to temperatures above 450°F.

Fiberfrax® Paper Family of products:

- 440

- Roll Board

- 550

- 970

- 880

- hsa

- 972-H

- 882-H

- HSA (of)

FIBERFRAX® COATINGS & SPECIALTIES

The Fiberfrax® Specialties family of products includes Fiberfrax

moldables, pumpables, caulks, coating cements, rigidizers,

tamping mix, and Moist-PackTM blanket. Many of these products

contain a wet, inorganic binder to provide both strength and

hardness at elevated temperatures. The range of product forms

provides a choice of materials to address a wide range of application

problems, such as resistance to hot gas erosion, flame

impingement, the ability to be formed into special shapes and

configurations, installation into blind hot spots and hard-toinsulate

areas.

Fiberfrax Specialties also possess the advantages inherent

with other Fiberfrax ceramic fiber insulating materials: high temperature

resistance, excellent insulating properties, thermal

shock resistance, chemical stability, and ease of installation.

Fiberfrax® Specialties Family of products:

- Moldables

- Pumpables

- Caulkings

- Cements

- Coatings

- Rigidizers

FIBERFRAX® SILPLATE® MASS 1500

Fiberfrax® Silplate® Mass 1500 is manufactured from the combination of high temperature fibrous materials and sintered high-purity, refractory oxides. Silplate Mass 1500 is a compound ready for application at temperatures up to 1500°C (2732°F). It may be applied on ceramic fiber insulation to form a surface that is highly resistant to abrasion and flame impingement.

Silplate Mass 1500 is applied on ceramic fiber lining systems with the following benefits:

- Increased abrasion resistance and durability

- Underlying fiber protected from shrinkage and/or chemical attack

- Minimized heat loss through cracks in the insulation

- Increased flue gas velocity resistance

- Heat Reflectance/Energy Efficiency

Silplate Mass 1500 is applied on hard refractory surfaces with the following benefits:

- Increased lining service life

- Reduced heat loss

- Increased operating temperature

- Heat Reflectance/Energy Efficiency

- Thermal shock protection

INSULFRAX® BLANKETS

Insulfrax® S Blanket from Unifrax was developed from a calcium,

magnesium, silicate chemistry to provide thermal insulation at

continuous operating temperatures up to 2012°F (1100°C).

Insulfrax S Blanket also meets European regulatory requirement

(Directive 97/69/EC). Insulfrax S fiber chemistry has been combined

with Unifrax’s proprietary fiber spinning technology to create

a specialty high-temperature blanket with superior thermal

and mechanical properties.

Insulfrax S blanket is used in a wide range of applications

including refractory linings, thermal insulation, appliances, and

molten metals transfer.

Insulfrax® General Characteristics:

Insulfrax S Blanket is a flexible, strong, lightweight, needled

blanket produced from Insulfrax Fiber. Mechanical needling of

the spun Insulfrax fibers eliminates the need for binders in the

product’s manufacture and results in a product with high tensile

strength. Since Insulfrax S Blanket is completely inorganic, the

product exhibits no smoke generation or outgassing in service.

Insulfrax S Blanket combines low thermal conductivity with

excellent resistance to thermal shock. Note that high humidity

and wetting with water prior to service has little effect on

Insulfrax S Blanket.

A series of green dots on the surface of the blanket make

identification, tracking, and inspection of Insulfrax S Blanket

simple on the job site or in the fabrication shop.

The Insulfrax Fiber calcium, magnesium, silicate chemistry

provides supe rior wetting resistance to molten aluminum alloys.

Testing with corrosive aluminum alloys at elevated temperatures

has proven that Insulfrax fibers are superior to traditional

alumina/silica refractory ceramic fibers.

Insulfrax® S Blanket Applications:

- Appliances

- Hearth Products

- Primary Metals

- Metals Processing

- Petrochemical/Power

- Ceramic and Glass

INSULFRAX® PAPER

Insulfrax® Paper is an evolutionary product which is

manufactured by forming Insulfrax Fiber in a nonwoven

matrix. These fibers are randomly oriented during

manufacturing and then held in place with a latex binder

system. A specialized paper-making process is utilized

to form uniform lightweight, flexible materials, including

Insulfrax Paper.

Insulfrax Fiber, utilized in Insulfrax Paper, is based upon

a calcium, magnesium, silicate (CMS) chemistry. This CMS

fiber chemistry has been successfully used to solve a

variety of application problems from 800°F (427°C) up to

2012°F (1100°C). In addition to high temperature resistance,

Insulfrax Fiber meets European regulatory requirements

(Directive 97/69/EC).

The calcium, magnesium, silicate chemistry of Insulfrax

Fiber provides superior wetting resistance to molten

aluminum alloys. Testing with corrosive aluminum alloys at

elevated temperatures has proven that Insulfrax is superior

to traditional alumina/silica refractory ceramic fibers.

Insulfrax Paper will generate small amounts of smoke

and trace element outgassing during initial exposure to

temperatures above 450°F (232°C).

Insulfrax® Paper Applications:

- Automotive and aerospace heat shields

- Gaskets for ovens, stoves, heaters, and other appliances

- Nonferrous ingot mold liners

- Refractory backup insulation in ladles, glass tanks, and

other high-temperature furnaces - Refractory backup insulation in ladles, glass tanks, and

other high-temperature furnaces - Molten aluminum transfer systems

FyreWrap® Marine Blanket

FyreWrap Marine Blanket from Unifrax is a totally inorganic,

flexible, high-temperature insulation blanket specifically

designed to provide passive fire protection for marine

applications. The calcia, magnesia, silica chemistry is

designed to enhance biosolubility. Unifrax’s proprietary fiber

spinning technology combined with mechanical needling of

the fibers eliminates the need for binders in the product. This

results in a material with high tensile strength and superior

thermal and acoustical properties. Insulfrax Marine Blanket

is chemically stable and its thermal properties are unaffected

after exposure to water immersion or high humidity.

FyreWrap Marine Blanket provides fire protection

insulation for a variety of rated assemblies on marine

structures and vessels. Thin, lightweight systems combined

with a flexible product form result in lower installation costs

and significant weight savings. This offers builders and

owners reduced structure weight, which may yield increased

vessel speed, fuel savings and available payloads. FyreWrap

Marine Blanket provides the following product features:

- U.S. Coast Guard approved for steel and aluminum

structures - Complies with SOLAS Safety Objectives and new

IMO FTP Code fire test requirements; Res.A.754(18) - Fire Resisting Division for High Speed Craft (HSC);

Res. MSC.45(65) - ABS (American Bureau of Shipping) approved for steel

and aluminum structures - Fire protection structural insulation for bulkheads

and decks - Significant weight savings versus mineral wool systems

- Flexible blanket is easy to cut and install

FyreWrap® Marine Blanket Applications:

FyreWrap Marine Blanket is utilized to insulate bulkheads

and decks on passenger and vehicle fast ferries, cruise

ships, commercial and military vessels, and offshore oil

platforms. Tested systems are in compliance with U.S. Coast

Guard regulations, now defined under IMO Res.A.754(18).

- Typical applications include:

- Steel bulkheads and decks

- Aluminum bulkheads and decks, including extruded thin

plate designs (min. 2mm thick) - Vehicle loading areas, engine rooms, storage areas, etc.

- Various H-Rated offshore structures (contact Unifrax for

details on tested systems and current certifications) - Non-combustible insulation