Products

Modules

Click Here for More Information...

Delta DF®/BN®/QS®/EM™/EG™/HC® Modules have the highest insulating value achievable in a ceramic fiber lining. Each module is comprised of folded blanket under compression to insure a tight seal and a “spring-back” action not found in typical wallpaper linings.

BLANKETS & SPECALTIES

Click Here for More Information...

High quality fiber blankets are the foundation of a sound insulated lining. Delta uses Unifrax blankets in many of its applications from our Delta Modules to insulating pads in textiles and wall paper linings.

We offer a full line of blankets, papers & specialty ceramic fiber and non-RCF products.

Monolithic Refractories

Click Here for More Information...

Delta Refractories provides a full line of monolithic refractories to all industries & all furnace types.

Our product line features:

Composite Shapes

Click Here for More Information...

Delta Composite Burner Tiles & Peepsight Surrounds were designed for high duty service in cracking, olefins, and reformer units. The unique composition of a dense castable hot face and vacuum formed backup, creates a product that withstands extreme furnace conditions & has excellent thermal properties.

Noted features of a Delta Composite Burner Tiles & Peepsight Surrounds are:

Corrosion Products

Click Here for More Information...

Delta Refractories is a proud distributor of Sauereisen products.

We currently distribute the following products:

Precast Shapes

Click Here for More Details...

Delta is a prominent manufacturer of value-added furnace shapes and an award winning distributor in the Refractory Industry. We design and cast a variety of simple & complex shapes for types of industries. All of our shapes are prefired to a minimum of 850°F and can be high fired if required.

Below are just a sample of the variety of shapes we manufacture:

IFB's & Firebrick

Click Here for More Information...

Delta Refractories works with numerous suppliers to provide the highest quality refractory brick in the industry. From 2300°F IFB straights & T/G brick to High Alumina RKB's & Arches/Wedges, Delta is able to source a plethora of different brick and pressed shapes to suit every need in the refractory industry.

We currently distribute the following products:

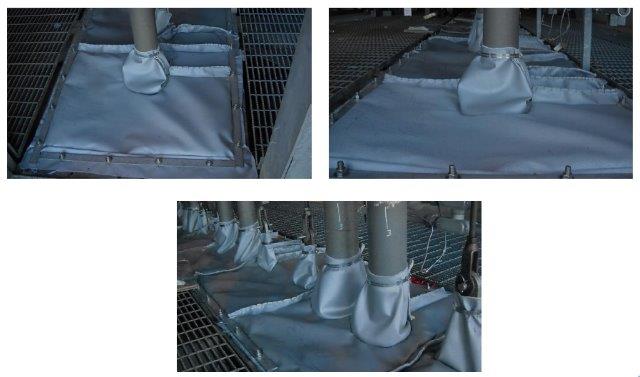

Seals & Gaskets

Click Here for More Information...

Delta supplies a full line of textile products to meet the demanding needs of the fabrication, oil & gas, and high heat industries.

Below are some of the products we supply:

Please visit our sister company at www.deltastudweld.com for a full line of anchors, studs, hardware, and custom components.